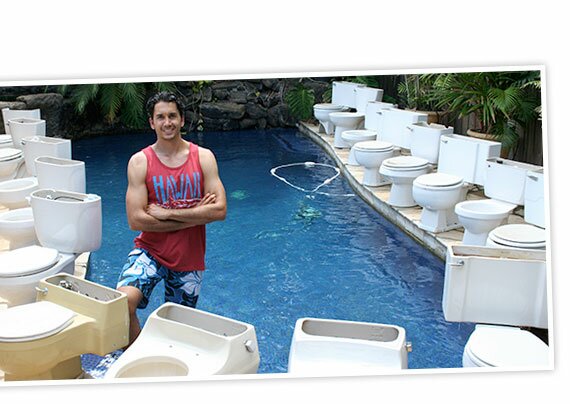

Pool Side Testing

It was discovered early-on that the time consuming flush testing process could be sped up significantly by moving the test facility to a swimming pool deck and modifying the flush testing procedure. Instead of waiting after each test flush for the toilets water fill valve to automatically re-fill, a 5-gallon bucket was used to manually re-fill the toilet tank after each test flush. Manually re-filling the toilet tanks decreased the flush testing time by an average of thirty seconds per flush. Thirty seconds may not sound like a long time, but when performing tens of thousands of test flushes, thirty seconds begins to add up quickly. Other benefits are that the pool-side test facility is located in Hawaii with great year-around weather; also thousands of gallons of fresh water were saved during flush testing. A wood ramp was placed beneath the toilets during test flushing, which channeled flushed water back into the pool for recycling.

Custom designed automated test fixtures for indoor laboratory testing where also used. Toilets were repeatedly cycled (dry-flushed) in excess of half a million flushes to test the integrity and durability of the Tap-n-Flush dual-flush converter. Testing proved that the Tap-n-Flush dual-flush system has the mechanical strength to withstand more than 50 years of flushing for a family of four, (More than half a million consecutive test flushes without failure).